專業導熱介面材料,提升系統散熱效率

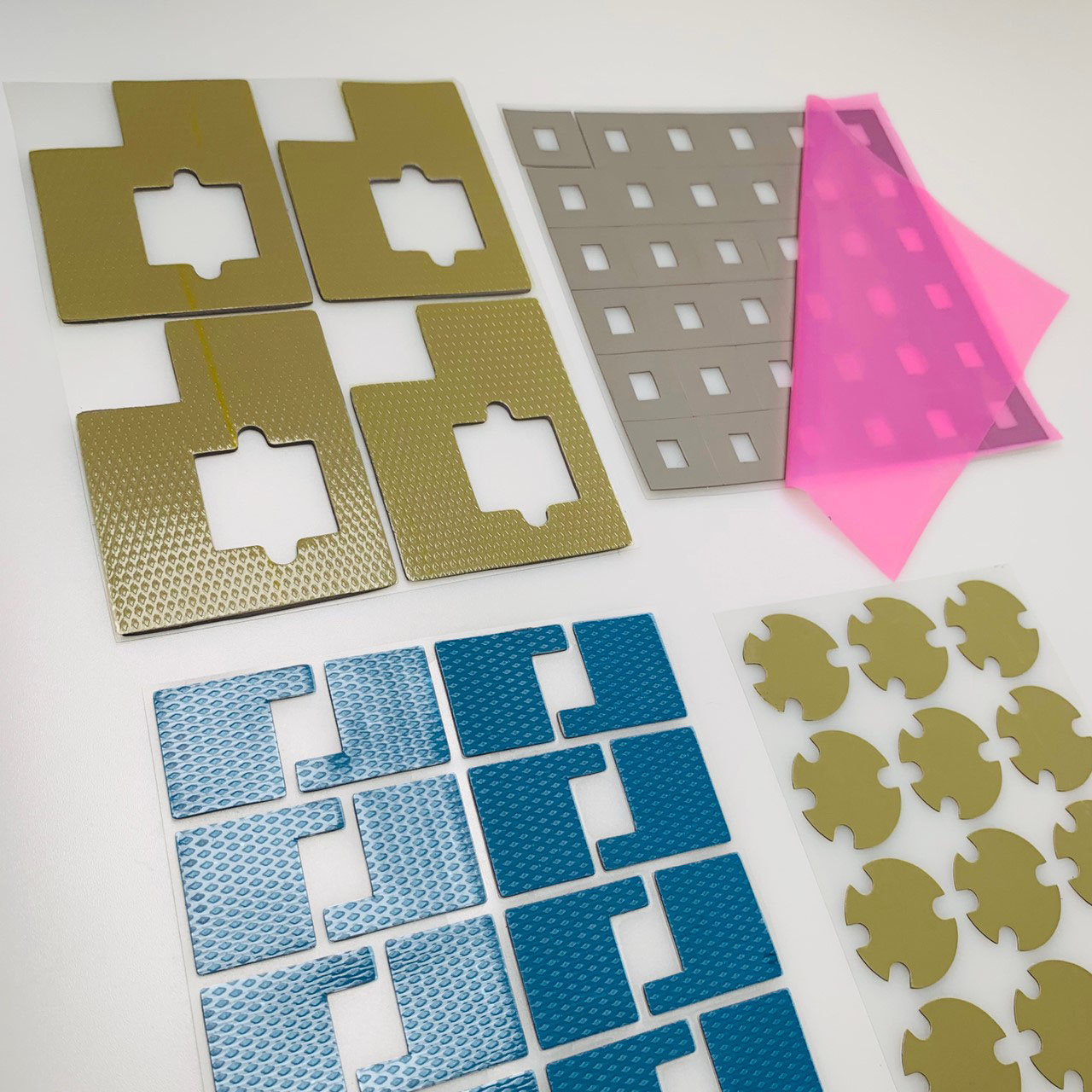

本系列 Thermal Pad 導熱片 / 導熱矽膠墊 / 導熱膠墊 / 導熱矽膠片 / 傳熱材料, 專為電子裝置熱管理需求設計。產品具備優異的導熱性能與彈性服貼性,能有效填補發熱元件與散熱片、外殼或模組間的微小縫隙,降低介面熱阻,實現穩定且高效的散熱效果。

產品特性

- 高導熱範圍:提供導熱係數 3~16 W/m·K,符合不同功率散熱需求。

- 多種硬度選擇:Shore 00 35~60,兼具柔軟度與支撐性。

- 無低矽氧烷揮發選項:特殊配方近乎無矽。可避免電器接點與電子板卡類之插卡端異常、防止對光學設備造成干擾,適用於光學投影、影像視訊等高精密電子產品。

- 可靠穩定:長期運作下仍能維持散熱效能與介面穩定性。

為您提供最佳散熱解決方案

無論是一般型導熱膠墊,或需近乎無矽之特殊材料,我們皆能依需求提供最合適的 Thermal Pad 導熱介面材料。

|

Product Number

(CTG-series) / Unit |

D160LG | D130RG | D110LM | D80LM | D60LS | D45RS | D32LS | 測試方法 Test Method |

|

|

|

|

|

|

|

||

| Color (顏色) |

Lt.Gray | Gray | Lt. Green gray | Lt. Purple gray | Peach-Red gray | Green-gray | Mud- Gray | Visual |

| Thickness Range (厚度範圍) mm |

0.5~1.0 | 0.6~7.0 | 0.6~8.0 | 0.6~8.0 | 1.0~10.0 | 1.0~10.0 | 1.0~10.0 | ASTM D374 |

| Thermal Conductivity (導熱係數) W/m.K |

16 | 13 | 11 | 8 | 6 | 4.5 | 3.2 | ASTM D5470 |

| Hardness(硬度) (Shore 00) | 65 | 60 | 55 | 50 | 40 | 35 | 40 | ASTM D2240 |

| Specific Gravity (比重) g/cm³ |

3.7 | 3.6 | 3.5 | 3.4 | 3.3 | 3.1 | 3.0 | ASTM D792 |

| Elongation (伸張度) % |

30 | 30 | 35 | 40 | 50 | 60 | 65 | ASTM D412 |

| Tensile Strength (抗拉強度) Kgf/cm² |

0.70 | 0.70 | 0.75 | 0.85 | 1.20 | 2.00 | 2.00 | ASTM D412 |

| Low Molecular Siloxane D3 to D20 Total (低分子矽氧烷) Wt(%) |

N.D. | 0.018 | N.D. | N.D. | N.D. | 0.038 | N.D. | Gas Chromatography |

| Volume Resistance (體積阻抗) Ohm.cm |

> 1013 | > 1013 | > 1013 | > 1013 | > 1012 | > 1011 | > 1011 | ASTM D257 |

| Dielectric Breakdown Voltage (耐電壓) KV/mm |

> 8 | > 8 | > 8 | > 8 | > 6 | > 6 | > 6 | ASTM D149 |

| Operating Temperature Range (操作溫度範圍) ℃ |

- 40 to +200 | - | ||||||

| Flame Resistance (阻燃性) |

V-0 | UL-94 | ||||||